Applying bacterial inoculants to forage is a crucial component of successful forage fermentation.

Bacterial silage inoculants: your silage quality improvement tool

Applying bacterial inoculants to forage is a crucial component of successful forage fermentation. While indigenous microorganism populations cause fermentation to occur naturally, the use of bacterial inoculants aids and directs the process, resulting in overall better quality silage.

Beneficial Bacteria

Forage naturally contains species of homofermentative and heterofermentative bacteria. Homofermentative bacteria produce almost exclusively lactic acid, whereas heterofermentative bacteria may produce ethanol, CO2 and/or acetic acid, in addition to some lactic acid. Without any additives, homofermentative and heterofermentative species compete to determine the environment of the fermenting forage.

Silage inoculants typically feature homofermentative species of bacteria, since a homofermentative ensiling environment results in reduced dry matter loss, improved palatability, and better retention of nutrients and energy, among other benefits. More recently, silage inoculants have been developed which feature heterofermentative species of bacteria. While these products show promise in terms of increased bunk life stability during feedout, homofermentative silage inoculants remain the most reliable choice for achieving anaerobic stability and improving the quality of all silage types.

Homofermentative bacterial strains used in silage inoculants are selected for their ability to grow rapidly under a range of temperature and moisture conditions. Bacterial species commonly found in silage inoculants include Lactobacillus plantarum or other Lactobacillus species, Pediococcus species, and Enterococcus faecium. Applying bacterial inoculants is beneficial only if live bacteria reach the crop. It is essential that bacterial inoculants are properly stored according to manufacturer instructions in order for the bacteria to remain viable.

to improve silage quality.

Enzymes

Silage additives also commonly feature enzymes. Enzymes break down components in the forage, and produce sugars that beneficial bacteria can more readily use in the fermentation process. Silage additives may feature cellulases, hemicellulases and pectinases, which break down the digestable fiber portion of forage, and amylase, which breaks down starch.

FermenAider™ provides more than face value

FermenAider™ silage inoculants produced by Bio-Vet deliver viable, naturally occurring

microorganisms and enzymes to the crop to ensure that efficient silage fermentation occurs. FermenAider™ is available for dry granular (DG) or water soluble (WS) application. FermenAider™ DG guarantees a lactic acid bacteria (LAB) count of 182 billion colony forming units (CFU) per pound. FermenAider™ WS guarantees 90.8 billion CFU per gram. For effective fermentation, it is recommended that a minimum of 100,000 CFU of LAB be applied per ton of forage. Bio-Vet recommends applying FermenAider™ DG or WS at the following rates depending on conditions:

- Minimum 100,000 CFU per ton of forage for ideal

ensiling conditions - Minimum 200,000 CFU per ton of forage for

normal ensiling conditions - Minimum 400,000 CFU per ton of forage for

difficult ensiling conditions

FermenAider™ contains five strains of homofer-mentative bacteria, including Lactobacillus

plantarum, Pediococcus pentosaceus, Pediococcus acidilactici, Lactobacillus brevis, and Lactobacillus casei.

fermentation process:

- Pediococcus acidilactici and Pediococcus pentosaceus rapidly lower pH during the initial

phase of fermentation, - Lactobacillus brevis promotes aerobic stability in the forage, and

- Lactobacillus plantarum and Lactobacillus casei serve to keep pH levels low and stable

throughout the fermentation process.

FermenAider™ also contains the enzymes amylase, cellulase, B glucanase and hemicellulase. FermenAider™ treated forage sample.

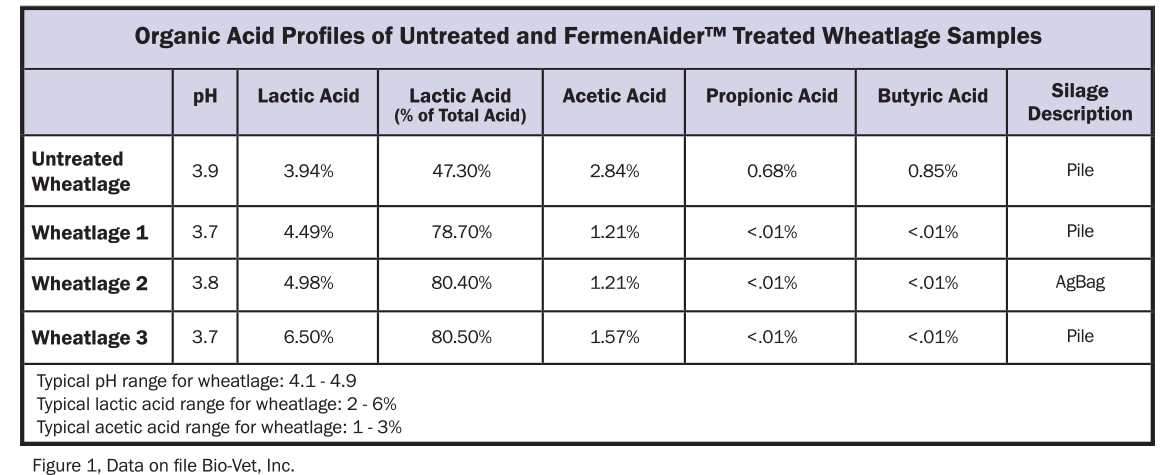

When homofermentative bacteria successfully dominate the fermentation process, the resulting silage will exhibit a lower pH, with higher levels of lactic acid relative to other end products of fermentation. Figure 1 contains data from untreated wheatlage and selected treated wheatlage samples. The untreated wheatlage sample had a lower than typical pH, but higher than typical levels of propionic and butyric acid, suggesting that a partial clostridial fermentation may have occurred. Clostridial fermentation frequently results in a loss of dry matter and energy along with reduced bunk life.

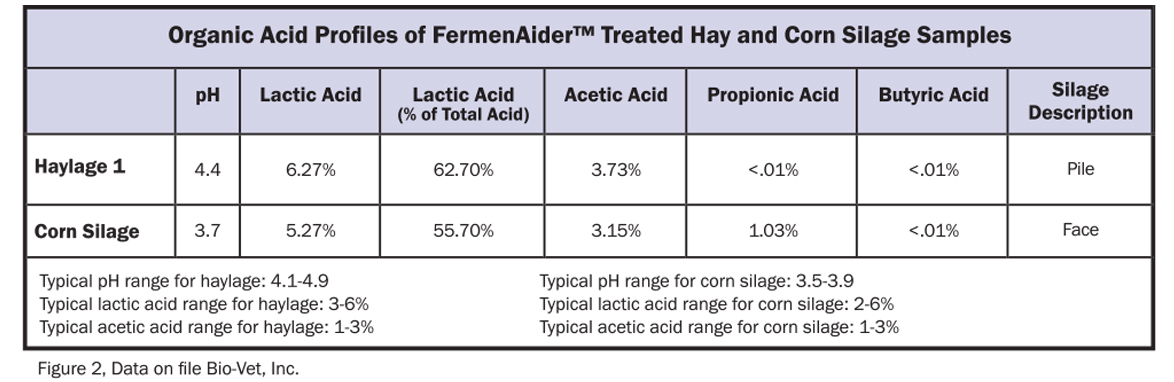

The application of a bacterial inoculant can help prevent clostridial fermentation by rapidly dropping the pH of the fermenting forage, helping to inhibit the growth of clostridial bacteria. Figure 1 also contains selected wheatlage samples treated with FermenAider™. Of the treated silage samples shown , all demonstrated that an efficient fermentation occurred. The final pH levels of the samples are lower than the typical pH range for wheatlage (4.1-4.9), and lactic acid dominates the percentage of total acids. In FermenAider™ treated haylage and corn silage samples, shown in Figure 2, the pH falls within the typical pH ranges for haylage (4.1-4.9) and corn silage (3.5-3.9) The haylage sample exhibits a lactic acid percentage that is above the typical

haylage range (3-6%), and the lactic acid value for the corn silage sample falls within the typical range (2-6%).

Bacterial inoculants are a key part of successful silage fermentation, but not the only consideration. Generally speaking, five factors determine the fermentation process: the forage moisture content, the fineness and type of chop, the exclusion of oxygen, the carbohydrate content of the forage, and the bacterial populations present on the forage, both indigenous and as a result of inoculation. Good silage management practices include rapidly filling, properly packing, and covering the storage structure. The crop type, storage structure type, and feedout rate must also be taken into consideration. Bacterial silage inoculants are best viewed as a silage quality improvement tool, and one that provides significant economic benefit.

Feed High Quality Forages with Bio-Vet in three easy steps

ONE

FermenAider™ Silage Inoculant

FermenAider™ WS (Water Soluble)

FermenAider™ HELPS GENERATE:

- More rapid and complete fermentation

- Improved retention of forage nutrients

- Better silage stability

- Improved silage value

- Three convenient application rates for various conditions

TWO

Generator™ ULTRA Direct Fed Microbial

Start 21 days prior to calving and feed through 150 days of lactation

- P169 for propionate production

- P63 utilizes lactic acid for rumen health

Generator™ ULTRA Unlocks More Energy from feedstuffs.

THREE

Kuro FX™

- Reed-sedge peat

- Hydrolyzed yeast cell walls

- Aluminosilicate

- Vitamin A

- 7 B-vitamins